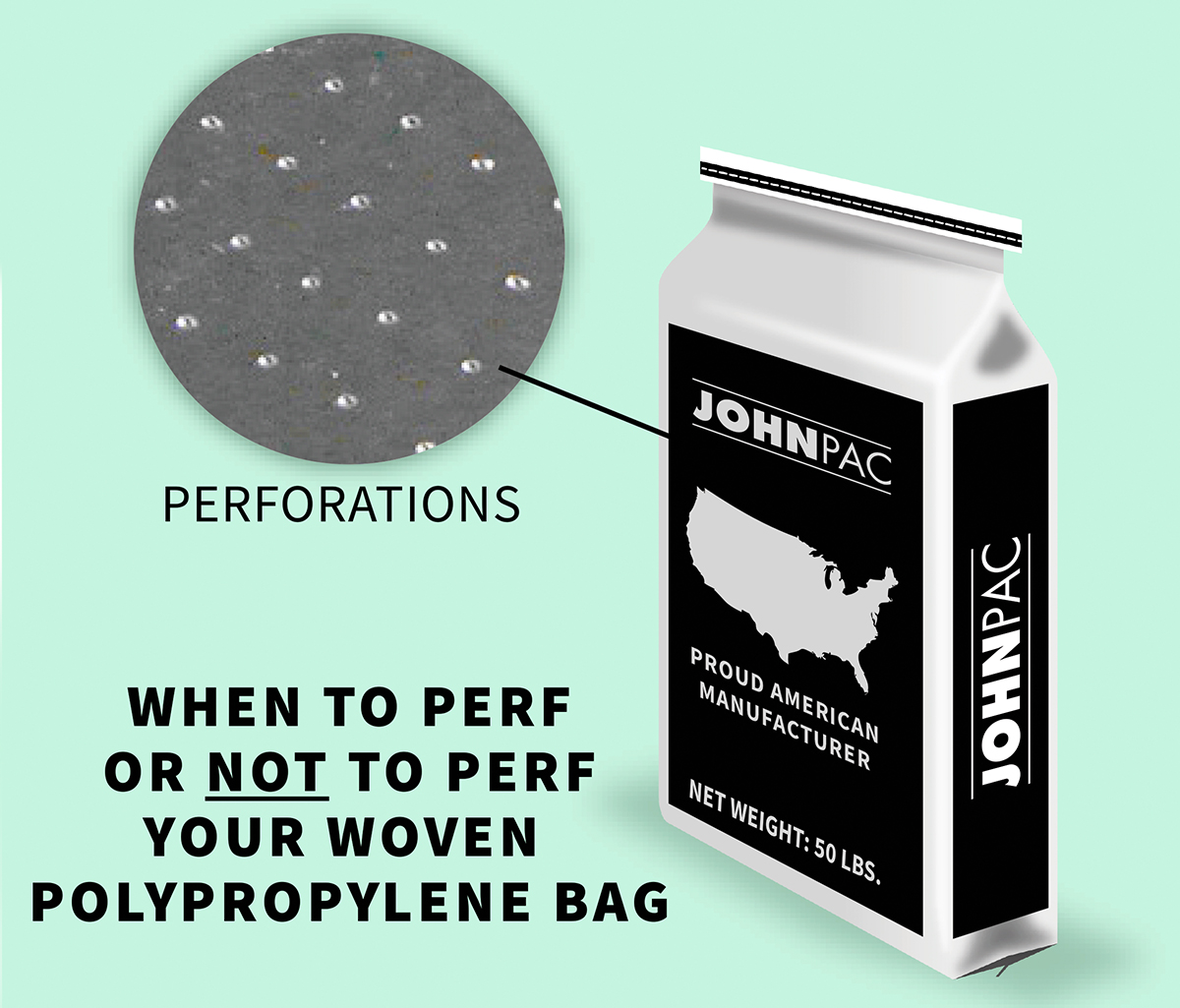

Perforated versus non-perforated woven polypropylene bags

Which is right for your product?

Packaging needs to protect your product from damage in transportation, look good on the retail shelf, and also preserve your product’s freshness, especially

when that product is food grade. One way our woven polypropylene bags conserve the grains and feed inside is through perforation. But not every product

needs their bag perforated.

So which bag is right for your product…perforated or non-perforated? Well, that depends on factors such as the moisture content in your product,

what temperature is your product upon filling the bag, and where will your bag be stored. These small, purposely place holes are an easy addition in

the manufacturing process, but getting them when you don’t need them-OR NOT getting them added when you do-can have devastating consequences. Such

consequences can be mold due to excess moisture caused from bag sweating in hot temperatures or product dry out.

We supply a wide variety of woven polypropylene bags, from BOPP for superior graphic quality to surface print to keep your packaging economical. In addition

to how our woven bags look, we also care about their performance. Consult one of our woven bag experts to pair the best bag style and construction for your product!

FILL OUT THESE QUESTIONS ABOUT YOUR BAG / GET EXPERT ADVICE AND A QUOTE